Blog

-

The California Air Resources Board (CARB) and the Preemption List

The California Air Resources Board (CARB) regulates, among other things, the emissions from combustion

-

Pressure Gauges Are Just One Tool For System Monitoring

Pressure gauges are an important tool for monitoring systems in many areas of industrial processes. However,

-

-

-

Sprinkler System Booster Pumps

Why Sprinkler system booster pumps

Why do you need a water booster pump? While household water -

Prepare for Dewatering constructions sites and fields During the Spring Melt

Dewatering can be necessary at almost any time of the year but is particularly prevalent in the spring.

-

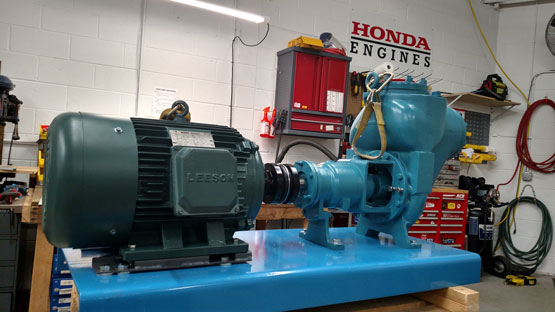

Custom Pumps For Your Application

At Pumpbiz we work with customers to ensure the pumps and components they purchase are right for their

-

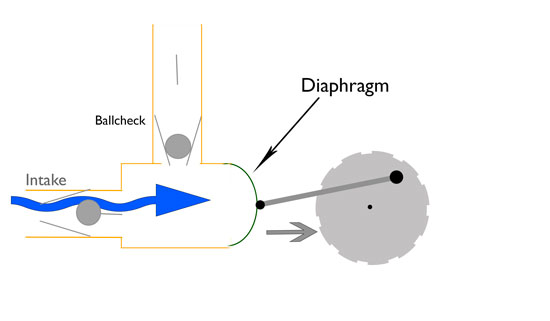

How Do Diaphragm Pumps Work

Diaphragm pumps are widely used in industrial and residential applications. These pumps are reliable

-

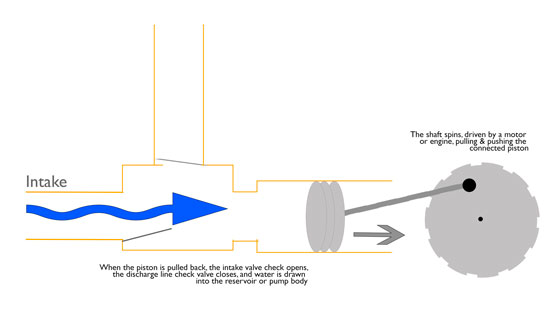

What is a plunger pump? What would I use a Plunger Pump for?

Water or liquid pumps use the properties of a vacuum to move liquids along a path through intake and

-

Choosing Gas Pumps vs. Electric Powered Pumps

So you’ve decided what type of pump works best for your particular application, now it’s time to dec

-

Sump Pump Maintenance Tips

Based on our data from the last 5 years, historically we see a spike in sump pump purchases each Spring.

-

Hot Oil Pump Applications

What is a hot oil pump?

A hot oil pump, or thermal oil pump, is exactly what

-

Spring Pond Pump Maintenance

With spring around the corner, people are anxious to be outside and start enjoying their gardens and

-

High pressure water pumps vs high-flow water pumps

Water pumps are used for many different applications. From things we do at home to municipalities, to

-

Explosion Proof Pumps: Who needs them? What are they?

What is an Explosion Proof Pump & Where is it Used?

Who needs an explosion-proof pump?

-

Food Grade Pumps

There are pumps for many different types of applications. Some of the applications require pumps made

-

Submersible Pumps: What Are They And Are They Worth It?

Whether you’re in need of a pump for an industrial operation or you just need to clear out a flooded b

-

The right residential fire pump

Homeowners looking for fire pumps need to be careful; the right pump and right equipment are vital and

-

CBD Extraction & Pumping Equipment

Over the past decade, the United States has experienced an explosion in demand for hemp products. One

-

Types Of Water Hoses

The term “water hose” can be used for many different applications. But, before you just buy a water hos

-

Sprinkler Pump Maintenance

We demand a lot out of pumps. In addition to the immense pressure under which they operate, there are

-

-

Irrigation For Hemp Growers

As you can imagine, the variety of irrigation systems mean there is also a wide range of pumps that can

-

6 Common Water Pump Questions

As the year comes to a close, we look back on the questions people most often ask about water pumps.

-

What Makes A Pump A “Chemical Pump”?

As you might expect, chemical pumps are designed to handle fluids that are corrosive or abrasive. While

-

Preparing your water pump for winter

We use outdoor water pumps or fountains, irrigation systems, pond aeration and much more. But when winter

-

Buying American Made Water Pumps

Buying American products is more than a symbolic show of patriotism. It has real effects on the world

-

Flooding: Prepare, Stay Safe, Clean Up

We get a lot of calls about which pumps are best to deal with flood waters. Dewatering after a flood

-

Once the storm passes: Dealing with the flood

The aftermath to a disaster may seem almost as daunting as the storm itself. But reliable equipment and

-

Dealing with the Storm

Remember, preparation and information are the most important parts of getting through a disaster. Establish

-

Preparing For Flooding

The first step in dealing with floods is understanding and preparing for the risks. Knowledge and planning

-

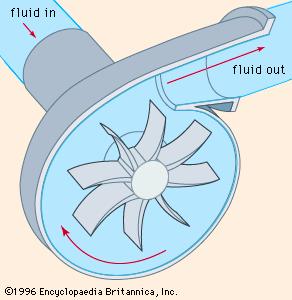

Sanitary NSF Pumps: What Is The Certification

Sanitary NSF Pumps for food processing, beverage production and potable drinking water. These include

-

Calif Prop 65

The California Office of Environmental Health Hazard Assessment is establishing this website to provide