Finish Thompson Pumps (FTI)

Finish Thompson Inc. FTI industrial Chemical pumps enjoy a reputation for state-of-the-art pump engineering, quality, delivery, as a diversified manufacturer of industrial chemical solvent acid pumps. FTI Pump Product line ranges from drum pumps to centrifugal pump and vertical pumps, magnetic coupled / magdrive (with true run-dry capability) and mechanical sealed centrifugal pumps along with AODD. Finish Thompson also makes ANSI dimensional magnetic drive process pumps for chemicals. Pumps for DEF Diesel Exhaust Fluid, alcohol, bleach, FDA compliant included. Materials: PP, PVDF, ECTFE and 316 SS. ISO 9001. Replace Lutz Flux. USA Made in PA.

FTI mag drive centrifugal pumps are used in a couple of areas in ethanol plants with Explosion Proof motors for flammable liquid transfer. They transfer sulfuric acid that is used to decrease pH in the fermentation section and are also used to pump clean in place (CIP) solutions like nitric acid and sodium hydroxide.

-

BT Finish Thompson High Viscosity Solvent Drum Pump

The BT series is rated for mild corrosives and flammables of high viscosity in applications which require high head. Use for pumping polymers, adhesives, oils, resins, etc. up to 15,000 cps. Features • Sealed • Tube interchangeable with motors • Easy disassembly for cleaning • Stainless Steel and PTFE construction• 12 FT power cord • On / Off switch Caution: When pumping flammables, must use air or Explosionproof motors and static protection...

-

Drum Pump Kits

Finish Thompson Drum Pump Kits Include tube, motor, and discharge hose packed in one carton. FTI barrel pump kits available in PolyPro PP, Kynar PVDF, Stainless Steel SS and with electric, Explosion Proof and Air motors. Drum pump tubes come in lengths from 27" to 72" used on totes. These industrial drum pumps handle all sorts of chemicals (acids to caustics), solvents, oils, soaps and food products. Liquids from think to thick high viscosity. Barrel pumps for transfer of all types of chemicals,...

-

TT Solvent / Semi-viscous Drum Pump

Finish Thompson Inc. Stainless Steel drum pump. The TT series Stainless Steel drum barrel pumps are ideal for corrosive chemicals or solvents, flammables, and applications requiring high purity or sanitary construction. Designed for semi-viscous liquids, inks, detergents, vinegar, and motor oils are a few typical uses. Viscousity limits: 2,000cps air motor and 400cps with electric motor. The tubes and motors are interchangeable. Available with electric or air pneumatic motors. Electric motors are rated...

-

VKC10 Vertical Mag Drive Pump 70gpm

Vertical Mag Drive Pump by Finish Thompson Using rare-earth Neodymium magnets, VERTIMAG chemcial pumps achieves a truly sealless, vertical pump design free of wetted shaft bearings. Vertical chemical pump completely sealed, air tight column and the absence of a secondary / back impeller prevent aeration (virtually eliminating micro-bubbles in PCB plating aplications) and the release of fugitive environmental emissions.VERTIMAG answers conventional vertical pump applications within a wide range...

-

UC Sealless ANSI Chemical Pump 325gpm

Finish Thompson ANSI / ANSI B73.1M dimensional Chemical Process mag drive pumps. Engineered for EXTREME reliabilty in chemical processes. The ULTRAchem pumps are rugged CI shells with a solid Tefzel fluoropolymer for the most demanding chemical resistance. Rare earth neodymium magnetic coupling provides reliable torque for liquids up to 1.8 sg and up to 20 HP. Available in 3 casing sizes, multiple impeller trims. All Finish Thompson chemical pumps mount to NEMA or IEC motors. Shaft is solid sintered...

-

Finish Thompson Pump KC22/32 MagDrive 240gpm

Finish Thompson Inc. pump. Magdrive sealless pumps designed for chemical processing and the highest level of reliability. All series KC pumps from FTI feature Neodymium Rare-Earth magnets. The resultant superior Finish Thompson benefits over traditional ceramic mag pumps include: RUN DRY for 10 minutesUSE OF STD. NEMA MOTORSHANDLE UP TO 1.8 S.G.MAGNETIC COUPLING NOT AFFECTED BY HIGH TEMPERATURESVIRUALLY UNBREAKABLE CANTILEVERED CERAMIC SPINDLE Series KC pumps are available in Polypro and Kynar®, sizes...

-

HVDP High Viscosity Drum Barrel Pumps

High Viscosity Drum Pump. Finish Thompson HVDP Series drum pumps are positive displacement pumps using a progressive cavity design to gently move highly viscous materials up the pump tube in a smooth, non-pulsing flow. The progressive cavity design requires a relatively slow speed to operate properly. A planetary gear set speed reducer enables the HVDP Series pumps to accept 800 watt universal, induction or air motors. Progressive cavity design Up to 100,000 cP: adhesives, viscous fluids/pastes, oils,...

-

DEF Pump Urea Transfer System

DEF Pump Urea Transfer Systems and pumps. Diesel Exhaust Fluid (DEF) is for diesel engine vehicles which use Selective Catalytic Reduction(SCR) to control NOx emissions. Finish Thompson dispensing systems are easy to use and provideeconomical, safe transfer of DEF from a variety of containers into the vehicles on-board Urea storage tank. FTI products are designed for years of reliable service while maintaining the strict purity requirements for DEF (ISO 22241-3). Urea DEF pumps also available as air...

-

Self Prime Magnetic pump

Self Priming magnetic coupled chemical pump by Finish Thompson Inc. FTI pumps are sealless magdrive design like no other pump. DB Magnetic Chemical Pump, SP Series pumps combine deep-lift capabilities and lightning-fast priming with the advantages of mag-drive technology, like no mechanical seal, neodymium magnetic drive system. End suction centrifugal and Self Priming pump versions share robust magnetic coupling technology. Five-year warranty Extended run dry ability (with carbon bushing) High...

-

Finish Thompson Chemical Industrial Drum Pump

Finish Thompson Chemical Drum Pump. Container emptying is accomplished quickly, efficiently and safely with FTI powered, portable barrel pumps. Utilizing FTI drum pumps, containers are filled or emptied without messy spills and splashes. Operator contact or exposure to potentially harmful chemical materials is avoided. All FTI pumps are designed with the user in mind. Can be mixed and matched with various electric and pneumatic motors. Pumps for alcohol and ethanol. Electric drum pumps are compact, have...

-

Chemical Pumps Finish Thompson AC4 AC5

Finish Thompson Chemical Pumps. Made from stainless steel alloy. Rugged, metallic sealed centrifugal AP Series pumps are compact in design, easy to operate and handle, and very economically priced. Built from high quality 316 stainless steel the AP Series chemical pumps are available in both horizontal or vertical designs. All wetted parts are constructed of very corrosion resistant materials to withstand the harshest chemical environments. Compared to 304 stainless steel, 316 stainless...

-

TM Drum Mixers Finish Thompson

The TM Series Drum Mixer is a 4-blade, turbine drum mixer ideal for mild corrosives, solvents, or other light to medium viscousity fluids which need mixing. Non-aerating, non-vortexing circulation blending action. Tube can interchange with air, electric or EXP motors. Good for liquids to 1,000 cps. Maximum 14 gpm circulation. Chemical Drum Pump

-

DB Magnetic Chemical Pump FTI

DB series magnetic drive pump by FTI. the new standard. DB Magnetic Chemical Pump, sealless magdrive pump like no other. End suction centrifugal and Self Priming pump versions share robust magnetic coupling technology DB5.5 Centrifugal pump magdrive DB6 Centrifugal pump magdrive DB7 Centrifugal pump magdrive DB8 Centrifugal pump magdrive DB9 Centrifugal pump magdrive DB10 Centrifugal pump magdrive DB11 Centrifugal pump magdrive DB15 Centrifugal pump magdrive DB22 Centrifugal pump...

-

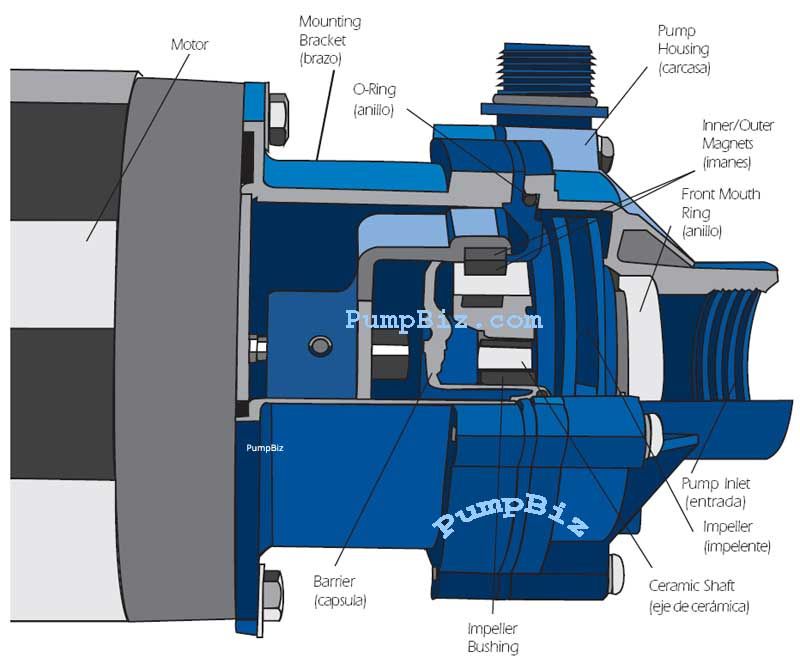

KC5.5 Centrifugal pump magdrive 31.5gpm

Centrifugal pump. Magdrive sealless pumps designed by Finish Thompson FTI for chemical processing and the highest level of reliability. All series KC cpumps from FTI feature Neodymium Rare-Earth magnets. The resultant superior benefits over traditional ceramic magnetic centrifugal pumps include: RUN DRY ENDLESSLY in a centrifugal pump USE OF STD. NEMA MOTORS HANDLE UP TO 1.8 S.G. MAGNETIC COUPLING NOT AFFECTED BY HIGH TEMPERATURES VIRUALLY UNBREAKABLE CANTILEVERED CERAMIC SPINDLE Series KC...

-

KC6 MagDrive 33gpm 23psi

Magdrive sealless industrial pumps designed by Finish Thompson for chemical processing and the highest level of reliability. All series KC pumps from FTI feature Neodymium Rare-Earth magnets. The resultant superior benefits over traditional ceramic mag pumps include: RUN DRY ENDLESSLY USE OF STD. NEMA MOTORS HANDLE UP TO 1.8 S.G. MAGNETIC COUPLING NOT AFFECTED BY HIGH TEMPERATURES VIRUALLY UNBREAKABLE CANTILEVERED CERAMIC SPINDLE Series KC magnetec pumps are available in Polypro and Kynar®,...

-

KC11 Mag Drive to 94gpm

Magdrive sealless pumps designed for chemical processing and the highest level of reliability. All series KC pumps from FTI feature Neodymium Rare-Earth magnets. The resultant superior benefits over traditional ceramic mag pumps include: RUN DRY for 10 minutes USE OF STD. NEMA MOTORS HANDLES UP TO 1.8 S.G. The Max. Operating pressure 35 psi (1.0 sg). MAGNETIC COUPLING NOT AFFECTED BY HIGH TEMPERATURES VIRUALLY UNBREAKABLE CANTILEVERED CERAMIC SPINDLE Series KC pumps are available in Polypro (P)...

-

KC6H Magnetically Coupled pump 38gpm

Magnetically coupled pump = sealless pumps designed for chemical processing and the highest level of reliability. The KC6H is a High-Head version of the popular KC6 series. All series KC pumps from FTI feature Neodymium Rare-Earth magnets. The resultant superior benefits over traditional ceramic mag pumps include: RUN DRY ENDLESSLY USE OF STD. NEMA MOTORS HANDLE UP TO 1.8 S.G. MAGNETIC COUPLING NOT AFFECTED BY HIGH TEMPERATURES VIRUALLY UNBREAKABLE CANTILEVERED CERAMIC SPINDLE KC6H pumps are...

-

KC10 Magnetic Drive pump 70gpm

Magnetic drive pump, sealless Chemical pumps designed by Finish Thompson for chemical processing and the highest level of reliability. All series KC magnetic drive pumps from FTI feature Neodymium Rare-Earth magnets. The resultant superior benefits over traditional ceramic mag pumps include: RUN DRY ENDLESSLY USE OF STD. NEMA MOTORSHANDLE UP TO 1.8 S.G.MAGNETIC COUPLING NOT AFFECTED BY HIGH TEMPERATURESVIRUALLY UNBREAKABLE CANTILEVERED CERAMIC SPINDLE Series KC pumps are available in Polypro...

-

KC8 Mag Drive to 67gpm

Magdrive sealless pumps designed by Finish Thompson for chemical processing and the highest level of reliability. All series KC pumps from FTI feature Neodymium Rare-Earth magnets. The resultant superior benefits over traditional ceramic mag pumps include: RUN DRY ENDLESSLY USE OF STD. NEMA MOTORSHANDLE UP TO 1.8 S.G.MAGNETIC COUPLING NOT AFFECTED BY HIGH TEMPERATURESVIRUALLY UNBREAKABLE CANTILEVERED CERAMIC SPINDLE Series KC pumps are available in Polypro and Kynar®, sizes range from KC3 to KC32...

-

Drum Pump motors

Drum barrel pump motors, electric & air for use with Finish Thompson Inc. FTI drum pumps. Drum pump motors are available as Electric or Air Pneumatic motors. Most motors and drum pump tubes are interchangeable. Simply disconnect one from the other. The Electric are available in Open, Enclosed and EXPlosion Proof (Hazardous Duty) enclosures and voltages of 115, 230 and rechargeable battery DC. UL, CSA and ATEX approved These motors are compatible with the FTI drum barrel pumps and Economy chemical...

-

TB Stainless Drum Pump light viscousity

Finish Thompson Inc. Stainless Steel drum pump. The TB series Stainless Steel drum barrel pumps are ideal for corrosive chemicals or solvents, flammables, and applications requiring high purity construction. Designed for light viscous liquids, solvents, vinegar, and disinfectants are a few typical uses. Viscousity limits: 200cps air motor and electric motor. The tubes and motors are interchangeable. Available with electric or air pneumatic motors. Electric motors are rated intermitant duty. Archimedes...

-

Economy Drum Pump - EF Series Sealless Drum Pumps

Drum / Barrel Pumps Economy series EF, low flow Sealless, Best Value This pump provides an economical, medium duty, choice for transfer at lower flow or in a lab setting. Ideal replacement for hand pumps. For container-to-container transfer of acids, corrosives and chemicals. Polypropylene (PP), pure PP/PVDF Kynar and 316SS tubes Interchangeable with motors, electric, Explosion Proof and air pneumatic for flammable liquids Dual speed adjustable motors Built-in hose, cord clips, & strainer...