Oberdorfer Pumps

-

N Oberdorfer Gear Pumps Bronze

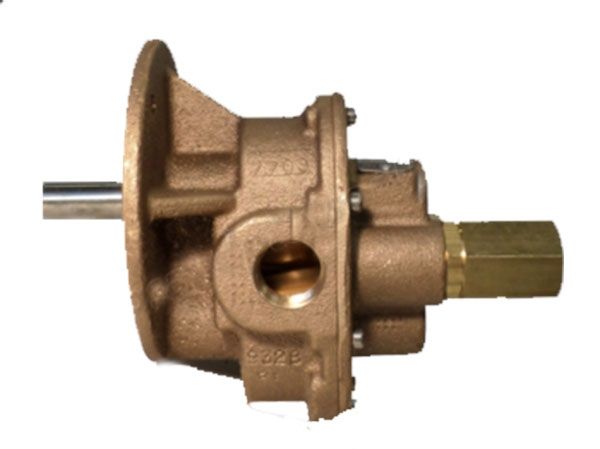

Oberdorfer Bronze Gear pumps Pump housings and gears are made of top quality bronze, shafts are from stainless steel 303. Bearings are designed of high performance carbon-graphite material selected for wear resistance and long service life. Gear pumps are positive displacement pumps. Each shaft revolution displaces a definite amount of l9iquid relatively unaffected by the back pressure in the discharge line. Shaft speed and flow are directly proportional. Recommended pressure limits are 100 psi for water...

-

N970 Oberdorfer Bronze gear pump 3/4

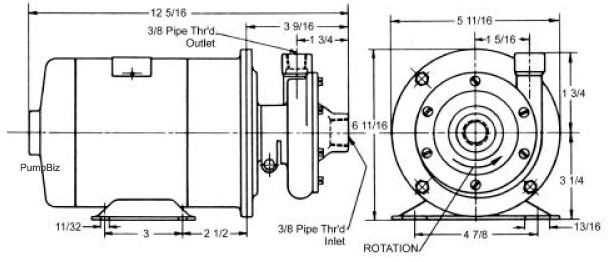

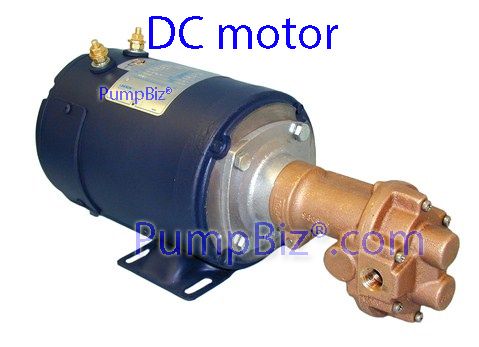

Oberdorfer Close coupled 3/4" bronze rotary gear pumps. Available as pump end only PEO or coupled to a NEMA standard frame motor. Pump housings and gears are made of top quality bronze, shafts are from stainless steel 303. Bearings are designed of high performance carbon-graphite material selected for wear resistance and long service life. Gear pumps by Oberdorfer are positive displacement pumps. Each shaft revolution displaces a definite amount of liquid relatively unaffected by the back pressure...

-

N999 Bronze Gear pumps

Bronze gear pumps with or without electric motors. Pump housings and gears are made of top quality bronze, shafts are 303stainless steel. Bearings are designed of high performance carbon-graphite materialselected for wear resistance and long service life. Gear pumps are positive displacement pumps. Each shaft revolution displacesa definite amount of liquid relatively unaffected by the back pressure in thedischarge line. Shaft speed and flow are directly proportional. Recommended pressurelimits are 100 PSI...

-

N26 2 Gear Pump

Pedistal Rotary Bronze Gear pumps. Design features an outboard ball bearing support for belt drive applications. Self lubricating carbon bearings. Pressures to 140 PSI.

-

Bronze Rotary Gear Pumps

This Bronze Rotary Gear Pump is popular among OEM users. It is a diesel fuel transfer and heli-arc welding cooling pump featuring an all bronze design and 303 stainless steel shafts with options of non-metallic gears and a variety of shaft seals. Special Features: Bronze Body Helical Gears for Quiet Operation Self-lubricating Carbon Bearings Buna N Lip Seal Carbonator Motor Mount Bronze pumps are suitable for water, oil, and mild chemicals in the pH-range from 4-10. Viscous liquids may be handled...

-

N990 Close Coupled Bronze Rotary Gear Pumps

Oberdorfer Bronze gear pump. Close coupled bronze rotary gear pumps. Available as pump end only PEO or coupled to a NEMA standard frame motor. Pump housings and gears are made of top quality bronze, shafts are from stainless steel 303. Bearings are designed of high performance carbon-graphite material selected for wear resistance and long service life. Gear pumps are positive displacement pumps. Each shaft revolution displaces a definite amount of liquid relatively unaffected by the back pressure in the...

-

SM103 Magnetic Drive

Designed to handle highly corrosive liquids that must be pumped under pressure. The Chemsteel pump prevents system contamination while maintaining the purity and integrety of the liquid being pumped. Key attributes include: Slotted bearings to lubricate shaft and gear surfaces. Hydraulic porting to balance axial thrust and to reduce wear. Ample port sizing to redice the likelihood of cavitation when inlet pressure is marginal. Effective housing seals with elastic memory prevent leakage...

-

300B Marine AC Water Bronze Pumps

Oberdorfer Marine pump, Aluminum or Bronze self-priming mechanical sealed pump. Available with or without motor and Pedistal mounted. Used on many OEM marine AC units. Bronze models - Ideal for marine service ( air conditioning, bilge, and sea water recirculating).

-

N991 Bronze Gear Pump

Oberdorfer Pumps has been manufacturing high-quality, dependable pumps for over 100 years. We manufacture gear pumps, centrifugal pumps, rubber impeller pumps, progressive cavity pumps, and roller pumps. Positive displacement BRONZE gear pumps. Little flow decrease with pump pressure increase. Flow increases with speed increase. Flow from 1-175 GPM (3 - 662 LPM)and pressures from 0-150 PSI (0 - 10.3 BAR). Pump housings and gears are made of top quality bronze, shafts are 303 stainless steel. Bearings are...

-

Bronze Centrifugal

Bronze Centrifugal pumps with moderately high pressure. Model 70P used in concrete cutting flat saws like Husqvarna, Diamond Boart, Norton and STW. Coolant to blades for floors, driveways, highways, streets, runways, new and old concrete and asphalt sawing cutting.

-

Bronze Centrifugal Pumps

Bronze Centrifugal Pumps, Close coupled . The impeller is attached directly to the motor shaft, the seal is a top quality face type mechanical seal. These pumps can handle small impurities in the liquid and the discharge line may be throttled without the need for a relief valve. Flow: 1-100 GPM (3 - 380 LPM) Pressure: 0-60 PSI (0-4.1 BAR) Performance: Flow drops to zero with maximum pressure output. Suction Lift (Water): Zero for straight centrifugal. 15 ft. with foot valve (4.6 meters) Self-priming...

-

N992 Gear Pumps

N992 Gear Pumps. Bronze gear pumps made in the USA

-

Sewage Transfer Macerator

Sewage Transfer Macerator. Rubber impeller, portable, bronze pump & motor. For water-like applications.

-

N1100 Bronze Gear pump CC 1.25

Close coupled 1 1/4" bronze rotary gear pumps. Available as pump end only PEO or coupled to a NEMA standard frame motor. Pump housings and gears are made of top quality bronze, shafts are from stainless steel 303. Bearings are designed of high performance carbon-graphite material selected for wear resistance and long service life. Gear pumps are positive displacement pumps. Each shaft revolution displaces a definite amount of liquid relatively unaffected by the back pressure in the discharge line. Shaft...

-

GearIron Gear Pump

GearIron®Cast Iron positive displacement helical gear pumps, General Duty series G, H is Heavy duty. Flow: 0-35 GPM (0-132.5 LPM) - Pressure: 0-500. Not for propane. PSI (0 - 34.5 BAR) Performance:Positive displacement. Little flow decrease with pump pressure increase. Flow increases with speed increase. Power: Power demand increases with speed and pressure. Suction Lift (water): 0-20 ft. below pump level (0 - 6.1meters) Liquid Cleanliness and Viscosity: Close tolerances require clean liquids. Viscous...

-

N9000 Pedestal Bronze Rotary Gear Pumps

Oberdorfer Pedestal Bronze Rotary Gear Pump. Often used as an oil pump on large ships to pre-lube the bearings, honey production systems. Pump flow is reversible. Bronze Corrosion Resistant Castings Model #'s with E have BSPT Special Cast Bronze Gears Stainless Steel Shafts & Fasteners Formed Ring Seal Packing (Lip & Mechanical Seals on Special Order) Heavy Duty Carbon Bearings (Self Lubricating) Carbon or Bronze (model #'s with L have bronze bearings) Positive Displacement Flow Pumps with relief valve...