What is a plunger pump? What would I use a Plunger Pump for?

Water or liquid pumps use the properties of a vacuum to move liquids along a path through intake and discharge ports. The initiation of the vacuum can be created in several ways.

Centrifugal pumps use a spinning impeller. Because of the nature of the impeller action, these pumps need to be primed in order to start liquid flowing through the system.

Diaphragm pumps and plunger pumps create a vacuum by expanding the space in an airtight reservoir. These are positive displacement pumps. However, they do this in different ways. We’ll cover the diaphragm pump in another article.

The Plunger Pump

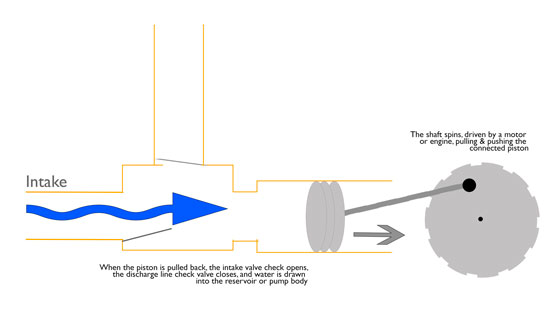

A plunger pump is also known as a piston pump. As you can probably surmise, the plunger/piston pump gets its name from the way it creates the vacuum in the pump housing. A piston is connected to a rotating wheel that draws in backward through a cylinder, thus creating a vacuum. This vacuum creates a suction force that draws fluid into the pump.

As this happens, two check valves are switched. The intake check valve opens, allowing water in. The discharge check valve closes, preventing backflow of liquid (or air if initiating pumping).

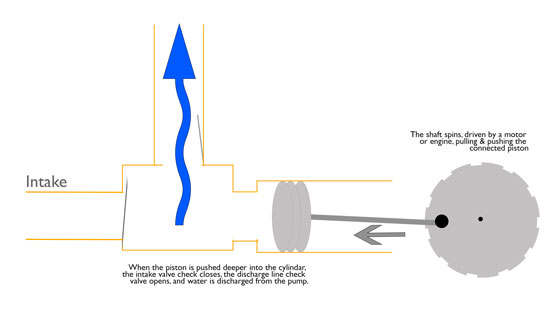

Once the piston completes its course to the top of the cylinder, the rotating shaft pushes the piston back into the cylinder, compressing the water and forcing it out the discharge port. This happens as the intake check valve is closed and the discharge check valve is opened.

What are the advantages of A Plunger Pump?

The greatest advantage of a plunger pump is the consistency of the pressure and volume of fluid that is pumped through the system.

Unlike the diaphragm pump which uses a flexible membrane as part of the process to create a vacuum, the plunger pump has all rigid parts. So, there is no variability and very little impact of wear and tear on the performance. Combining the type of construction of the pump with the use of pressure regulators, we can expect very consistent performance from plunger pumps.

Also, because the pump is composed of rigid parts, it can produce much higher pressure than other types of pumps.

Additionally, the plunger pumps work well with electric motors, often battery-powered. Using motors as the drive mechanism for the pump, they can run very quietly.

What are the applications for a Plunger Pump?

Most commonly, applications are residential and consumer-facing businesses top the list. Cleaning, lawn care, pest controls for residential applications.

Misters for cooling work well with plunger pumps. To prevent dripping, the pump for a mister must be extremely consistent, which is right in line with the key benefit of plumber pumps. Unlike diaphragm pumps, which can have somewhat inconsistent flow, causing the mister water to build upon and drip from the nozzle, piston pumps are consistent. Additionally, because the pumps can run with a quiet motor, they are ideal for residential or retail misting systems.

Think about other applications with similar needs to a misting system. Quiet pumps, consistent flow, and possible higher pressure requirements are ideal situations for a plunger pump.

You can see some of our lineup of plungers pumps/piston pumps from Pumptech here.